«Integra-Technologies» iDRILL

The history is closely connected with such a well-known enterprise of the oil industry of our country as VNIIBT-Drilling Tool, which, like us, is part of the Russian oilfield services Group of companies INTEGRA.

If we talk about the Integra Group of Companies, it was founded in March 2004 with the aim of forming a high-tech oilfield services group.

Currently, Integra Group holds one of the leading positions in Russia in the field of onshore oilfield services.

It was in the Perm branch of VNIIBT in 2001 that a decision was made to create an automated drilling system for the VZD, in 2015 a project was launched within the Integra group of companies, and in 2016 successful pilot work was already carried out.

Currently, Integra-Technologies is part of the Well Research and Mechanical Engineering Unit of the Integra Group of Companies.

If we talk about the Integra Group of Companies, it was founded in March 2004 with the aim of forming a high-tech oilfield services group.

Currently, Integra Group holds one of the leading positions in Russia in the field of onshore oilfield services.

It was in the Perm branch of VNIIBT in 2001 that a decision was made to create an automated drilling system for the VZD, in 2015 a project was launched within the Integra group of companies, and in 2016 successful pilot work was already carried out.

Currently, Integra-Technologies is part of the Well Research and Mechanical Engineering Unit of the Integra Group of Companies.

The main directions of the Integra-Technologies company:

- Development, production and modernization of automated drilling systems.

- Engineering support in the application of the electronic automated drilling system IDrill.

- Scientific research on the development of automation systems for drilling oil and gas wells.

- Training in specialized programs for engineering and technical workers of oil and gas producing and drilling, service companies (NSB).

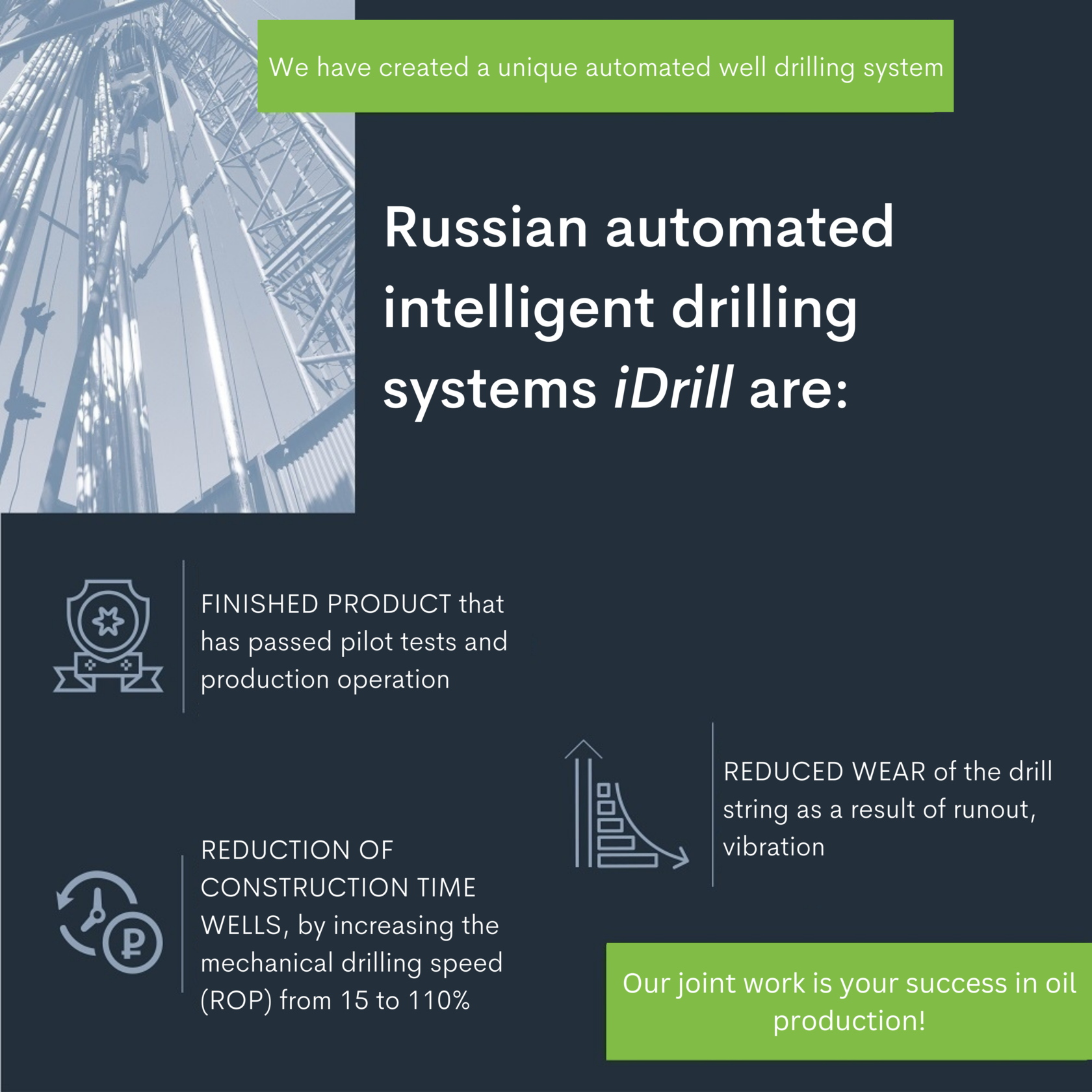

Features of innovation:

- Time - Increase in mechanical drilling speed.

- Shortening the well construction period.

- Quality - Improving the quality of the wellbore (reducing tortuosity). Effective control of the well trajectory during oriented drilling.

- Reliability - Reduction of runout, vibrations and wear of the elements of the BHA and the drill string. Improving the performance of the downhole engine. Increasing the service life of the chisel.

Objects of application and advantages of innovation:

- The object of automation is any drilling rig equipped with a drilling winch with manual mechanical brake control.

- Continuous automated control by electronics.

- Minimal influence of the human factor.

- The loading of the bit and the retention of the pressure drop do not depend on the driller's qualifications.

Certification:

- Complies with the requirements of the Technical Regulations of the Customs Union TR CU 004/2011 "On the safety of low-voltage equipment".

- Complies with the requirements of the Technical Regulations of the Customs Union TR CU 010/2011 "On the safety of machinery and equipment".

- The IDril automatic drilling control system is manufactured in accordance with the technical specifications of KBIZH.654299.001TU.

Advantages of using the system iDrill:

- A stable pressure drop is created.

- Uniform tool feed.

- Maintaining a differential pressure drop in a given range = constant torque on the shaft BACKWARDS = high-quality slides.

- The increase in the mechanical speed of penetration.

How does the drilling efficiency assessment take place?

- To assess the effectiveness of operations, various key performance indicators (KPIs) are used, which make it possible to identify hidden NIP.

- Sections are divided into flights, flights into operations, and operations into KPIs.

- We divide each individual operation into separate actions, namely KPIs. There are more than 700 KPIs in our system.

Automated complex «iDrill Pro»:

- A joint product of Integra and TDI Energy Services.

- Increase in mechanical speed + Detection of hidden NIP.

- To assess the effectiveness of operations, various key performance indicators (KPIs) are used, which make it possible to identify hidden NIP.

- Sections are divided into flights, flights into operations, and operations into KPIs.

- We divide each individual operation into separate actions, namely KPIs. There are more than 700 KPIs in our system.

BLOCK FOR DRILLING AND TECHNOLOGICAL SERVICES

BLOCK FOR WELL RESEARCH AND MECHANICAL ENGINEERING

BLOCK ON INFORMATIZATION AND AUTOMATION

FOR INVESTORS