Integra-Services, Tyumen

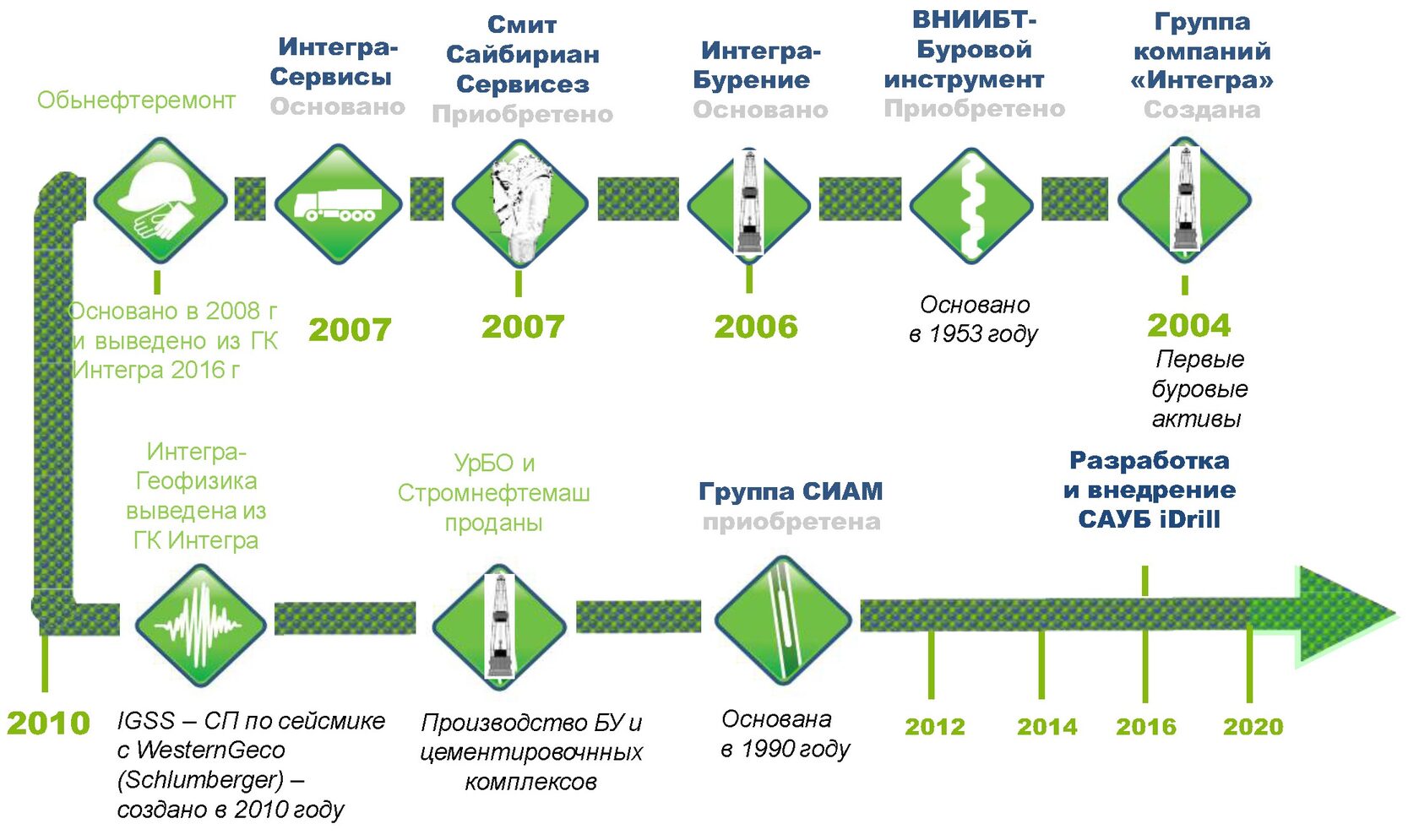

History of the INTEGRA Group

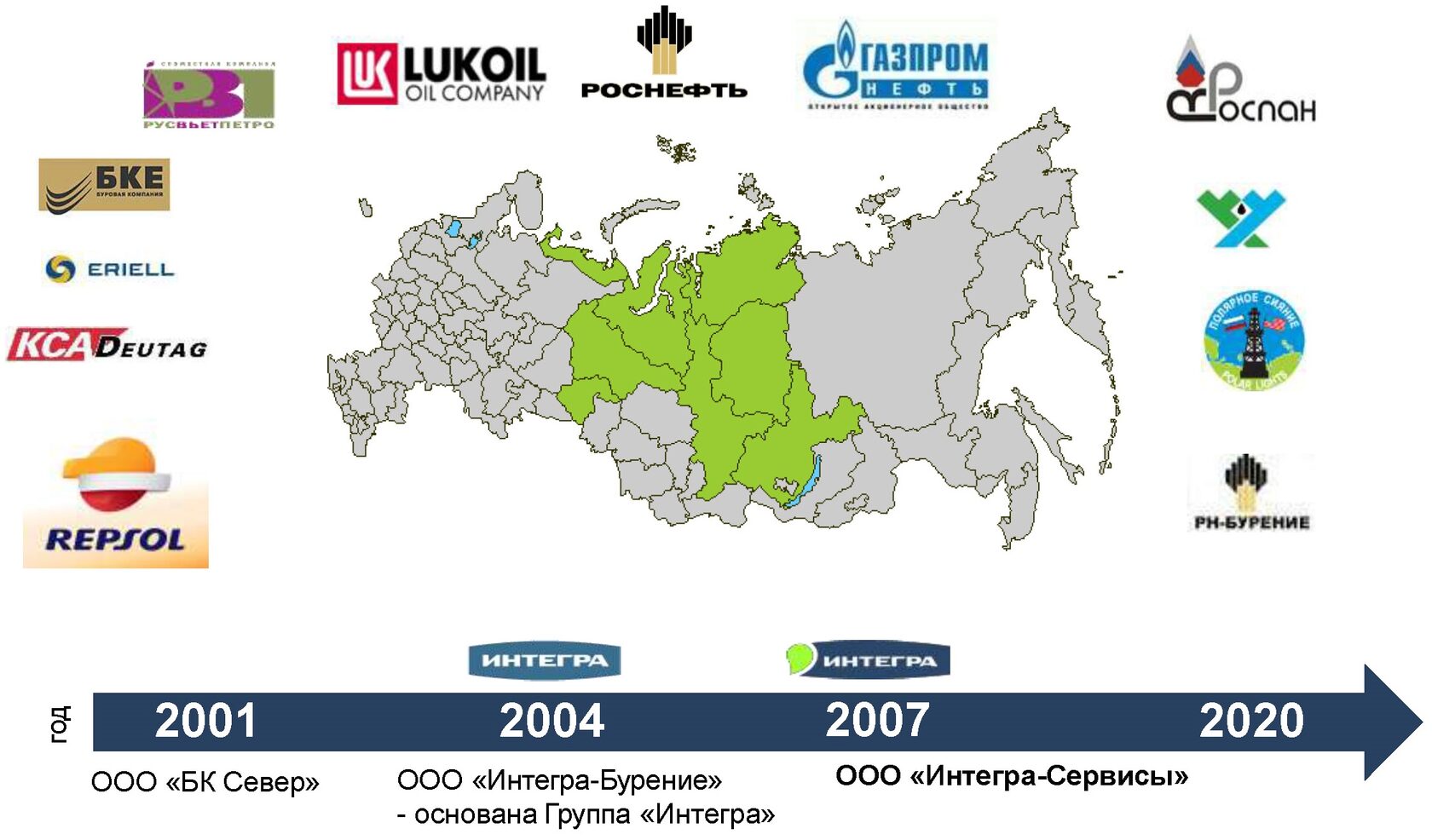

Regions of activity and customers of INTEGRA-SERVICES LLC

Quality and OT, PB and OOS.

Core values and principles in INTEGRA Group of Companies

Core values and principles in INTEGRA Group of Companies

The provision of services and strict compliance with HSE policies are the basis of Integra Group's business

Our values: Integra Group considers QHSE issues as the main value for business.

Integrated QHSE Management System:

Integra Group has implemented the IMPACT® Suite system for risk control, incident assessment, OD/OU;

All operations in Integra Group are performed in accordance with ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007 standards

QHSE corporate standards include:

2014 – HIS SPECTRUM Excellence Award

for the successful implementation of the innovative information product Impact ERM Suite

2015 – To win the first and second stages at the international competition

"Scientific, scientific, technical and innovative solutions aimed at the development of the fuel and energy and mining industries"

Integrated QHSE Management System:

Integra Group has implemented the IMPACT® Suite system for risk control, incident assessment, OD/OU;

All operations in Integra Group are performed in accordance with ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007 standards

QHSE corporate standards include:

- Standard of driving and trip management.

- HSE standards, training and Incident reporting standards.

- Service Quality Reporting Standard.

- Accident Investigation Manual.

- PPE Standard.

- OOS Standard.

- Audit standard.

- Guidelines, procedures for the preparation, organization and conduct of work.

2014 – HIS SPECTRUM Excellence Award

for the successful implementation of the innovative information product Impact ERM Suite

2015 – To win the first and second stages at the international competition

"Scientific, scientific, technical and innovative solutions aimed at the development of the fuel and energy and mining industries"

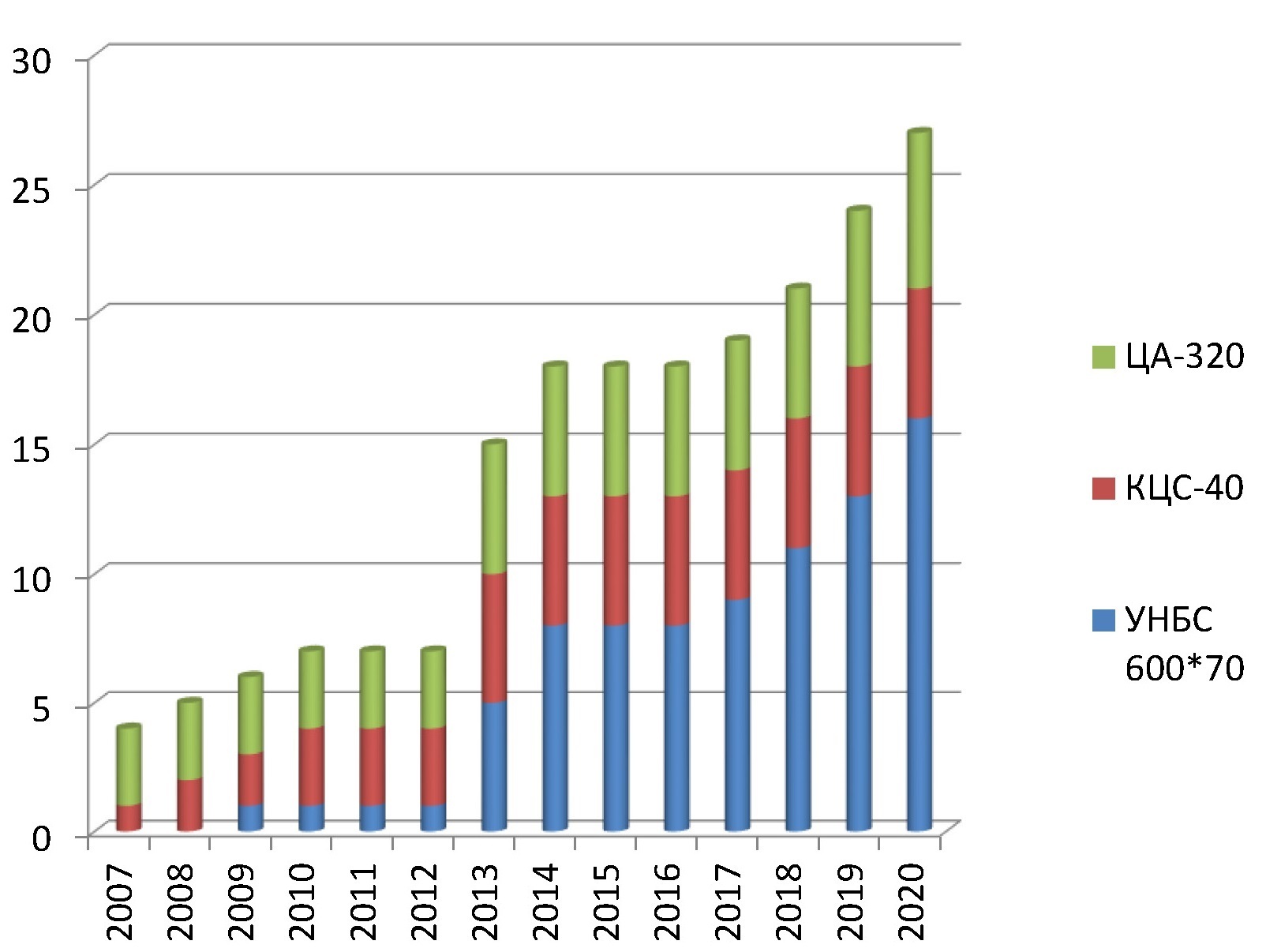

Dynamics of growth in the number of cementing fleets

UNBS

KCC-40

CA 320

Well cementing

25 cementing fleets

Cementing Complexes UNBS-2-600x70 – 16 fleets

• * 2 plunger pumps NTP 727, Cummins drive;

• Recirculating dust-free cement sealing system with pneumatic cement supply;

• SKUPTS – control and management of the cementing process;

• Compactness, mobility;

• Ural-Iveco 6339 chassis, gearbox: Allison automatic transmission, centrifugal pumps: Mission Sandmaster.

Cementing Complexes KTSS-40 – 5 fleets

• * Availability of two UOP averagers (20 m3) and URIR (10 m3);

• * 4 pumps;

• The possibility of using pumping units for simultaneous execution of various technological operations in drilling and in the development or repair of wells;

• High passability;

• Adaptation of the pumping group to work with pneumatic cement supply.

CA-320 cementing complexes (wheeled and sledge) – 6 fleets Plants for the preparation of dry cement mixtures

Cementing Complexes UNBS-2-600x70 – 16 fleets

• * 2 plunger pumps NTP 727, Cummins drive;

• Recirculating dust-free cement sealing system with pneumatic cement supply;

• SKUPTS – control and management of the cementing process;

• Compactness, mobility;

• Ural-Iveco 6339 chassis, gearbox: Allison automatic transmission, centrifugal pumps: Mission Sandmaster.

Cementing Complexes KTSS-40 – 5 fleets

• * Availability of two UOP averagers (20 m3) and URIR (10 m3);

• * 4 pumps;

• The possibility of using pumping units for simultaneous execution of various technological operations in drilling and in the development or repair of wells;

• High passability;

• Adaptation of the pumping group to work with pneumatic cement supply.

CA-320 cementing complexes (wheeled and sledge) – 6 fleets Plants for the preparation of dry cement mixtures

Well cementing

Availability of full-fledged winter packages for trouble-free work at temperatures up to - 50C

- Increased volume of measuring tanks;

- The presence of a 2 m3 averager;

- High-performance mixer (mixing of heavy cement with a capacity of 25 l/s);

- Transport dimension, no overweight;

- Reliable domestic three-plunger pumps with a long overhaul period;

- Possibility of changing pump sleeves 90, 100, 110, 125;

- Availability of several operator consoles;

- Full-fledged winter package: heating of plunger pumps, including power parts, under-roof

- space, hydraulic drives, power units, battery, engine chassis and cab.

Import substitution: Russian cement equipment

All cementing equipment is world-class, high-tech and manufactured according to specifications at SIBNEFTEMASH and BETSEMA plants

KAMAZ 65221 truck tractor

Cementing unit UNB 2

Mobile temporary storage warehouse for dry cement mixtures CT-40 (40 m3)

Cement truck CT-16

Cement truck CT-25

Well cementing experience

Cementing of wells with AVPD and acquisitions:

- Yurubcheno-Tokhomskoye field, 2009-2011

- Baykalovskoye field, 2010-2011

- Severo-Khosedayuskoye field, 2010-2014

- Nertsetinskoye field, Russian-Rechenskoye, etc.

- Khiagdinskoye field, Yurubcheno-Tokhomskoye, etc.

- Rospan International: well cementing of the Novourengoy and Vostochno-Urengoy fields (gas project), 2012-2015.

- RN-Uvatneftegaz: well cementing of the Tyamkinskoye and Yuzhno-Petyegskoye fields, 2011 - 2014

- Vankorneft: well cementing of the Vankorskoye field, 2011

- Gazprom Neft: twice the best cementing contractor at the Vostochno-Messoyakhskoye field, 2016-2017

Plants for the preparation of dry cement mixtures

Availability of modern plants for the preparation of dry cement mixtures

- Modern plants for the preparation of dry cement mixtures, including containers for packing, weighing cement, cleaning products from stones, sampling for subsequent quality control.

- Cement dust collection system during mixing.

Plants for the preparation of dry cement mixtures

Availability of equipment for conducting tests according to ISO standards 10 426-2,3,4,5,6

- Regional API Laboratory in Nyagan;

- 5 mobile laboratories;

- Selection of cement mortar formulations based on actual well conditions, samples of cement, water and chemicals from the field;

- Quality control of cementing materials and packed mixture;

- The staff is certified to work with Chandler Engineering, OFITE equipment;

- Thickening time

- Compressive/bending strength

- Rheology

- Water output

- Water output, sedimentation stability

- Expansion/Shrinkage

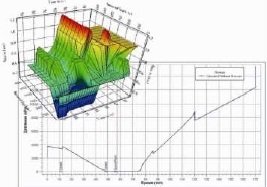

Computer simulation of work

Using modern software

- Opticum Landmark software package, Cempro +, CentraDesigh

- Hydraulic calculation of the cementing program (pressure at the mouth, at the bottom, fracturing of the formation, calculation of the risk of GNVP, U-Tubing);

- Selection of the optimal mode of well cementing, 3D modeling of substitution%;

- Calculation of column centering using actual well parameters (cavernometry, inclinometry).

BLOCK FOR DRILLING AND TECHNOLOGICAL SERVICES

BLOCK FOR WELL RESEARCH AND MECHANICAL ENGINEERING

BLOCK ON INFORMATIZATION AND AUTOMATION

FOR INVESTORS